Downhole Steam Generator for Heavy Oil Production

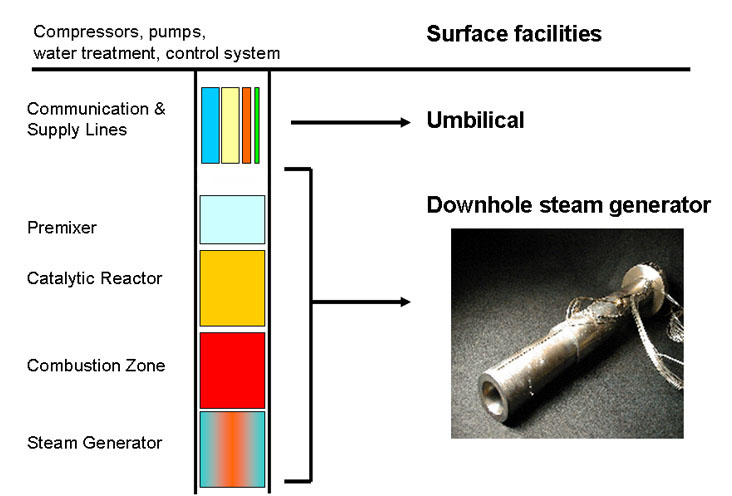

PCI is developing its downhole catalytic combustor steam generator for use in heavy or viscous oil production. Specific heavy oil products under development include 8 and 50 MM BTU/hr devices. PCI's direct-fired downhole steam generator offers substantial energy savings compared to current surface steam generators, delivering the entire BTU content of the fuel (including the higher heating value, and avoiding boiler losses as well as surface distribution and wellbore losses). In addition, the combustion products (CO2 and nitrogen, in addition to water) are injected into the reservoir rather than being released to the atmosphere, and additional CO2 could be added for sequestration purposes. Surface facilities deliver air, fuel and water to the downhole steam generator.

Surface steam generation for injection downhole is generally now required to produce large fractions of these reservoirs. The energy and environmental costs of surface steam injection are substantial. Energy costs of production can consume 20 to 30% or more of the BTU value of the produced oil, costing energy while also generating substantial greenhouse gas emissions.

Surface steam generation for injection downhole is generally now required to produce large fractions of these reservoirs. The energy and environmental costs of surface steam injection are substantial. Energy costs of production can consume 20 to 30% or more of the BTU value of the produced oil, costing energy while also generating substantial greenhouse gas emissions.

The PCI system integrates high stability catalytic combustion with steam generation in a downhole device attached through an umbilical to surface supply of high pressure fuel, air or oxidant, and water. PCI's design addresses key requirements for such as system, and has been demonstrated in subscale operation. A 5" OD system is suitable for generating 50 MM BTU/hr of heat at 100 atm.

PCI is seeking interested customers and partners in the oil and gas production field to advance this technology to field trial.

Contact PCI to learn more about how our solutions may be adapted for your needs.

Methane Hydrate Production-Downhole Steam Generator

Precision Combustion, Inc. (PCI) is developing a downhole catalytic combustor steam generator for efficient production of methane from its hydrate. Gas hydrate is a crystalline solid (see photo at right) consisting of gas molecules, each surrounded by a cage of water molecules. The gas is held in this state by a combination of low temperature and high pressure. If the gas could be effectively, safely and controllably tapped, gas hydrates offer the potential for making major contributions to meeting DOE primary objectives regarding energy needs and energy independence while substantially expanding available world energy reserves. Methane hydrate deposits are abundant throughout the world and have been estimated to represent the greater portion of the world’s fossil energy reserves. Estimates of hydrate natural gas on the North Slope of Alaska beneath existing facilities are in the 10's of trillions of cubic feet, with additional 100's of trillions of cubic feet in areas that do not yet have infrastructure. The estimates for hydrate natural gas beneath the U.S. continental margin is even larger, on the order of 1,000's of trillions of cubic feet (Sloan, et. al, 2008).

Methane hydrate deposits are abundant throughout the world and have been estimated to represent the greater portion of the world’s fossil energy reserves. Estimates of hydrate natural gas on the North Slope of Alaska beneath existing facilities are in the 10's of trillions of cubic feet, with additional 100's of trillions of cubic feet in areas that do not yet have infrastructure. The estimates for hydrate natural gas beneath the U.S. continental margin is even larger, on the order of 1,000's of trillions of cubic feet (Sloan, et. al, 2008).The U.S. Geological Survey estimates that methane hydrat may contain more organic carbon than all the world's coal, oil, and non-hydrate natural gas combined. The magnitude of this previously unknown global storehouse has raised serious inquiry into the possibility of using methane hydrate as a source of energy.[U.S. DOE Methane Hydrate Program].

[U.S. Geological Service]

Results from the U.S. Department of Energy Small Business Innovation Research project show that natural gas can be produced from its hydrate at an energy cost of approximately 15% of the heating value of the produced gas. A 5" OD device was designed to provide heat rates in the range of 50 MMBtu/hr at 100 atm. This is enough for 8.0 MM scf/day natural gas production assuming 15% consumption for production, as predicted by our modeling. Bench scale operation met the operational requirements to move to full scale high pressure single combustor testing, and a full scale design has been completed. The design is now ready to provide prototypes to producers and developers interested in a thermal stimulation tool for production of gas from hydrates.

Contact PCI to learn more about how our solutions may be adapted for your needs.

Soil Disinfestation Steam Generator

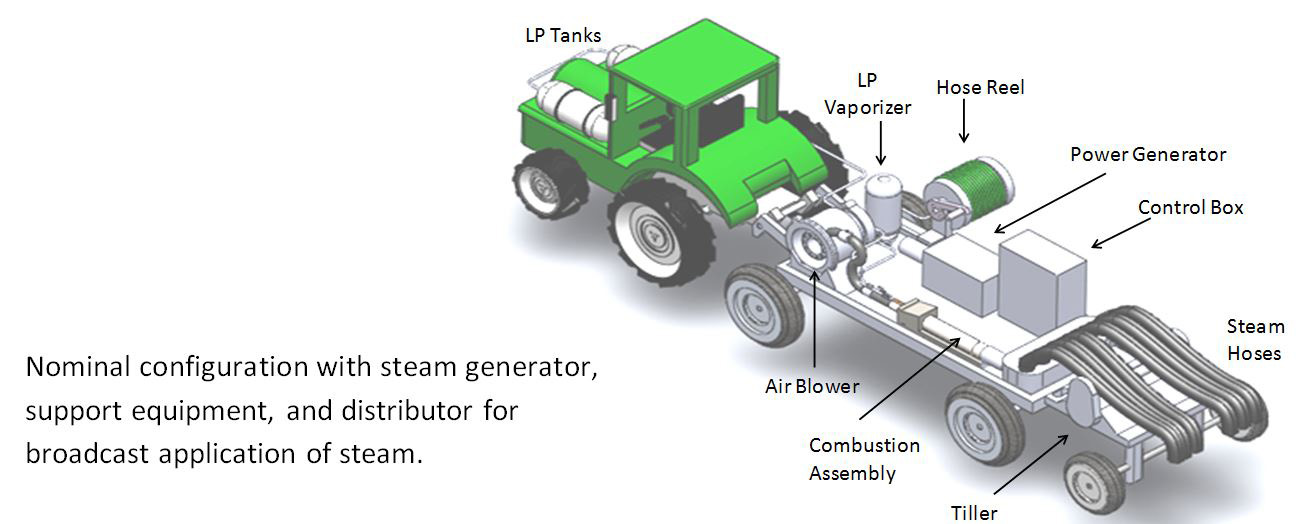

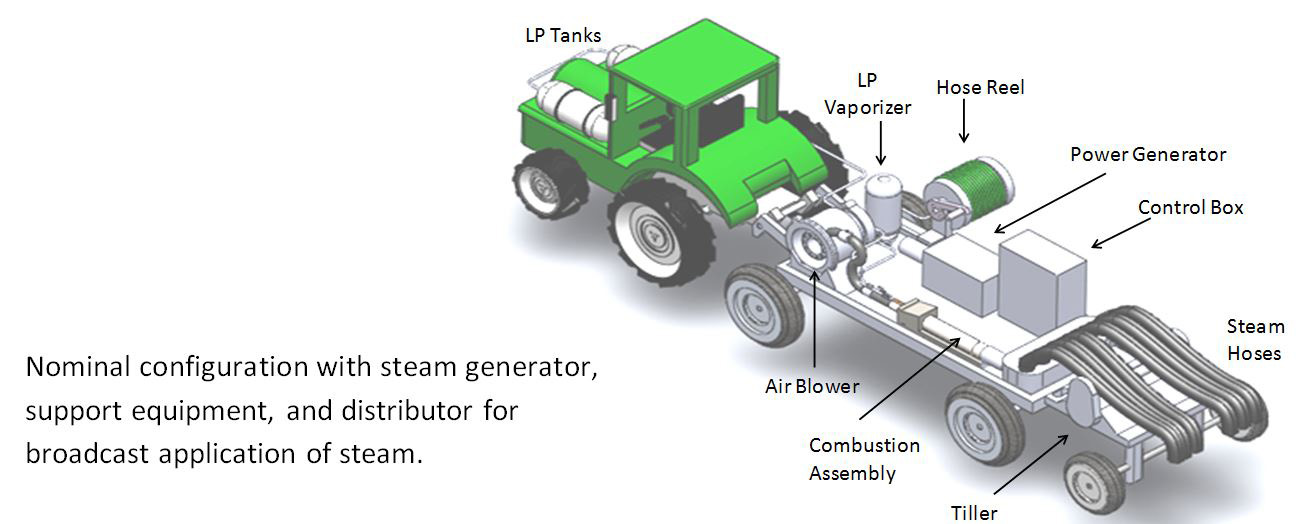

Precision Combustion, Inc. (PCI) is developing a low-emission, propane-fueled, direct-fired steam generating tool for soil disinfestation. This tool replaces pre-planting chemical fumigant applications for pest and weed control.

Steam has long been known as a highly effective method to control insects, nematodes and weeds but, up until now, it has not been possible to do so in a practical, cost effective manner for large acreage applications. The ability to safely control soil pests, weeds, and pathogens with steam, without the need for toxic fumigants, will enable effective cultivation of agricultural lands while eliminating or reducing food, worker, and surrounding non-farm area exposure to hazardous chemicals. Specifically with respect to organic produce, our soil disinfestation with steam will improve yields and quality while enabling growers to maintain their organic certification.

The product builds upon our extensive experience in catalytic combustors. Utilizing readily available propane or natural gas as a fuel source, we pass water through a chamber containing a proprietary catalyst bed which, in turn, generates large volumes of steam. This steam is conveyed to the soil via an applicator that controllably delivers the steam at an appropriate temperature and depth, thereby raising the soil temperature to a level that destroys undesirable pests and weeds.

PCI's catalytic combustor operates on propane, but can be adapted to other fuel sources. It does not require treated water, as conventional boilers do. Catalytic combustors are much more efficient than boilers in converting the energy of the fuel into usable steam. In addition to being more cost effective, emissions are significantly lower. Our product is integrated with other balance-of-plant equipment onto a self-propelled or tractor-pulled compact machine for high-rate high-efficiency steam treatment of planting beds and soils, suitable for large scale agricultural use.

Summarizing the advantages of PCI's catalytic steam generation technology as applied to soil disinfestation:Advantages of PCI's Catalytic Steam Generation Technology

- Easily generate temperatures required for pest and weed control;

- Significant energy savings from delivering full higher heating value of the fuel to the soil over conventional boilers;

- Zero hydrocarbon emissions, with low-single-digit ppm CO and NOx levels;

- Compact and lighter in weight than conventional boilers;

- Injection temperature can be controlled to produce super-heated steam for optimized disinfestation.

Contact PCI to learn more about how our solutions may be adapted for your needs.

test article for testing template design

Precision Combustion, Inc. (PCI) is developing a "At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas molestias excepturi sint occaecati cupiditate non provident, similique sunt in culpa qui officia deserunt mollitia animi, id est laborum et dolorum fuga. Et harum quidem rerum facilis est et expedita distinctio. Nam libero tempore, cum soluta nobis est eligendi optio cumque nihil impedit quo minus id quod maxime placeat facere possimus, omnis voluptas assumenda est, omnis dolor repellendus. Temporibus autem quibusdam et aut officiis debitis aut rerum necessitatibus saepe eveniet ut et voluptates repudiandae sint et molestiae non recusandae. Itaque earum rerum hic tenetur a sapiente delectus, ut aut reiciendis voluptatibus maiores alias consequatur aut perferendis doloribus asperiores repellat."

"At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas molestias excepturi sint occaecati cupiditate non provident, similique sunt in culpa qui officia deserunt mollitia animi, id est laborum et dolorum fuga. Et harum quidem rerum facilis est et expedita distinctio. Nam libero tempore, cum soluta nobis est eligendi optio cumque nihil impedit quo minus id quod maxime placeat facere possimus, omnis voluptas assumenda est, omnis dolor repellendus. Temporibus autem quibusdam et aut officiis debitis aut rerum necessitatibus saepe eveniet ut et voluptates repudiandae sint et molestiae non recusandae. Itaque earum rerum hic tenetur a sapiente delectus, ut aut reiciendis voluptatibus maiores alias consequatur aut perferendis doloribus asperiores repellat."

"At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas molestias excepturi sint occaecati cupiditate non provident, similique sunt in culpa qui officia deserunt mollitia animi, id est laborum et dolorum fuga. Et harum quidem rerum facilis est et expedita distinctio. Nam libero tempore, cum soluta nobis est eligendi optio cumque nihil impedit quo minus id quod maxime placeat facere possimus, omnis voluptas assumenda est, omnis dolor repellendus. Temporibus autem quibusdam et aut officiis debitis aut rerum necessitatibus saepe eveniet ut et voluptates repudiandae sint et molestiae non recusandae. Itaque earum rerum hic tenetur a sapiente delectus, ut aut reiciendis voluptatibus maiores alias consequatur aut perferendis doloribus asperiores repellat.".

Summarizing the advantages of PCI's catalytic steam generation technology as applied to soil disinfestation:Advantages of PCI's Catalytic Steam Generation Technology

- Easily generate temperatures required for pest and weed control;

- Significant energy savings from delivering full higher heating value of the fuel to the soil over conventional boilers;

- Zero hydrocarbon emissions, with low-single-digit ppm CO and NOx levels;

- Compact and lighter in weight than conventional boilers;

- Injection temperature can be controlled to produce super-heated steam for optimized disinfestation.

Contact PCI to learn more about how our solutions may be adapted for your needs.

Soil Remediation Steam Generator

Precision Combustion, Inc. (PCI) is applying its experience in catalytic combustion to the remediation of contaminated soils through the application of high pressure, high temperature steam directly into contamination zones. Building upon our experience in catalytic direct-fired steam generation, the products currently in development can be used as (i) a complementary process to other techniques; (ii) as the primary approach for cleaning up affected areas; and/or (iii) to create a barrier or "wall" around the perimeter of the pollution zone to prevent plumes from migrating to non-polluted areas, water zones, etc.

Precision Combustion, Inc. (PCI) is applying its experience in catalytic combustion to the remediation of contaminated soils through the application of high pressure, high temperature steam directly into contamination zones. Building upon our experience in catalytic direct-fired steam generation, the products currently in development can be used as (i) a complementary process to other techniques; (ii) as the primary approach for cleaning up affected areas; and/or (iii) to create a barrier or "wall" around the perimeter of the pollution zone to prevent plumes from migrating to non-polluted areas, water zones, etc.

Conventional thermal treatment technologies (electric conductive or resistive heating) are effective in removing contaminants, such as diesel fuel, crude oil, DNAPLs (dense non-aqueous phase liquids) and mercury, but these techniques are typically both costly and slow. A very large energy input is required to generate the required heat (>250 °C in the case of mercury), and long dwell times are required to elevate the soil region to the necessary temperatures. The high costs of thermal remediation present a significant barrier to effective and timely site restoration.

PCI's catalytic direct-fire steam generator avoids the inherent problems of conventional boilers. The disadvantages of boilers include high energy costs, high water usage, high CO2 emissions, as well as temperature limits of about 100 °C for saturated steam. PCI's approach eliminates the 30% to 45% efficiency losses suffered by conventional boilers.

PCI's catalytic direct-fire steam generator avoids the inherent problems of conventional boilers. The disadvantages of boilers include high energy costs, high water usage, high CO2 emissions, as well as temperature limits of about 100 °C for saturated steam. PCI's approach eliminates the 30% to 45% efficiency losses suffered by conventional boilers.

PCI's device is a catalytic direct-fired combustor system based on its well-established natural gas-fired catalytic combustor technology. The combustion process generates hot fluid, steam, and combustion end products N2 and CO2, with the steam containing about 70 % of the thermal energy produced. These fluids are injected into a perforated pipe section that release heat and mass flows into the contaminated soil zone, at temperatures from 100 to over 300 °C and at depths to at least 300 feet. The system will be compact, tightly controllable, and be capable of very high BTU output. The catalytic combustor is able to burn gaseous or liquid fuels.

The hardware can be configured to be placed into a pipe for insertion into the treatment area. Alternatively, the steam generation hardware could be located on the surface and the steam piped into the area via a manifold approach. In this setup, a single PCI device could support multiple injection wells, depending on the configuration and requirements for energy input, pressure and temperature.

Summarizing the advantages of PCI's catalytic steam generation technology as applied to soil remediation:Advantages of PCI's Catalytic Steam Generation Technology

- Easily generate temperatures required for remediation of oil contamination, DNAPLs and mercury;

- Significant energy savings from delivering full higher heating value of the fuel to the soil and from using less expensive energy sources over electric heaters;

- Zero hydrocarbon emissions, with low-single-digit ppm CO and NOx levels;

- Compact, fits within an injection pipe for targeted location temperature;

- Alternative configuration to manifold multiple injection points from a compact surface unit;

- Injection temperature can be controlled to produce super-heated steam for improved contaminant vaporization and removal.

Contact PCI to learn more about how our solutions may be adapted for your needs.