North Haven, CT (March 25th, 2024) - Precision Combustion, Inc. (PCI) announced today it was awarded an ARPA-E REEACH Phase 2 project titled “SOFCs for FLIGHT”. This follows PCI’s successful completion of its Phase 1 under the U.S. Department of Energy's Advanced Research Projects Agency-Energy’s (ARPA-E) REEACH (Range Extenders for Electric Aviation with Low Carbon and High Efficiency) program.

North Haven, CT (September 28th, 2023) - Precision Combustion, Inc. (PCI) announced today that it has won a Small Business Innovation Research (SBIR) Phase I award from the Navy to develop and integrate scalable and modular solid sorbent-based flue-gas carbon capture and storage (CCS) solutions for shipboard use. The project will focus on developing PCI's solid sorbent-based CCS technology for use on ships, including naval vessels. PCI’s approach offers to significantly enhance carbon capture rates and efficiency.

North Haven, CT (September 20th, 2023) - Precision Combustion, Inc. (PCI) announced today it was awarded a Small Business Technology Transfer Research (STTR) Phase II program from the Army to develop PCI’s fast startup, fuel flexible catalytic partial oxidation (CPOX) reformer technology. PCI’s reformer will enable smaller, lighter fuel cell systems operating on a variety of gaseous fuels including propane, methane, and biogases with varying compositions. This breakthrough is especially suitable for military portable power and unmanned vehicular power, as well as for commercial applications.

North Haven, CT (July 18th, 2023) – Precision Combustion, Inc. (PCI) announced selection for a highly competitive Small Business Technology Transfer (STTR) Phase I award from the National Aeronautics and Space Administration (NASA) to develop and demonstrate simultaneous hydrogen (H2) generation and compression using intermediate-temperature solid-oxide membrane, without moving parts. Leveraging a novel cell architecture, advanced materials, groundbreaking processing techniques and university relationships, PCI's innovation has the potential to improve efficiency and reliability for hydrogen generation and storage.

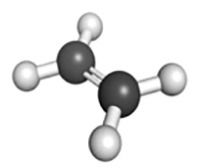

North Haven, CT (June 16, 2023) - Precision Combustion, Inc. (PCI) was awarded a Small Business Innovation Research Phase IIB program from the Department of Energy (DOE) for a new approach to producing ethylene from ethane. PCI's approach offers the potential for significant reduction in energy costs and carbon emissions. This process may also be applicable to the gas-to-liquid conversion of other alkenes to their olefins.

North Haven, CT (September 27th, 2022) - Precision Combustion, Inc. (PCI) announces it was awarded a Small Business Technology Transfer Research (STTR) Phase I program from the Army for their fast startup, fuel flexible catalytic partial oxidation (CPOX) reformer technology that is to be integrated into SOFC systems. This project is targeted to develop a technology to support efficiently converting hydrocarbon fuel sources to electricity.

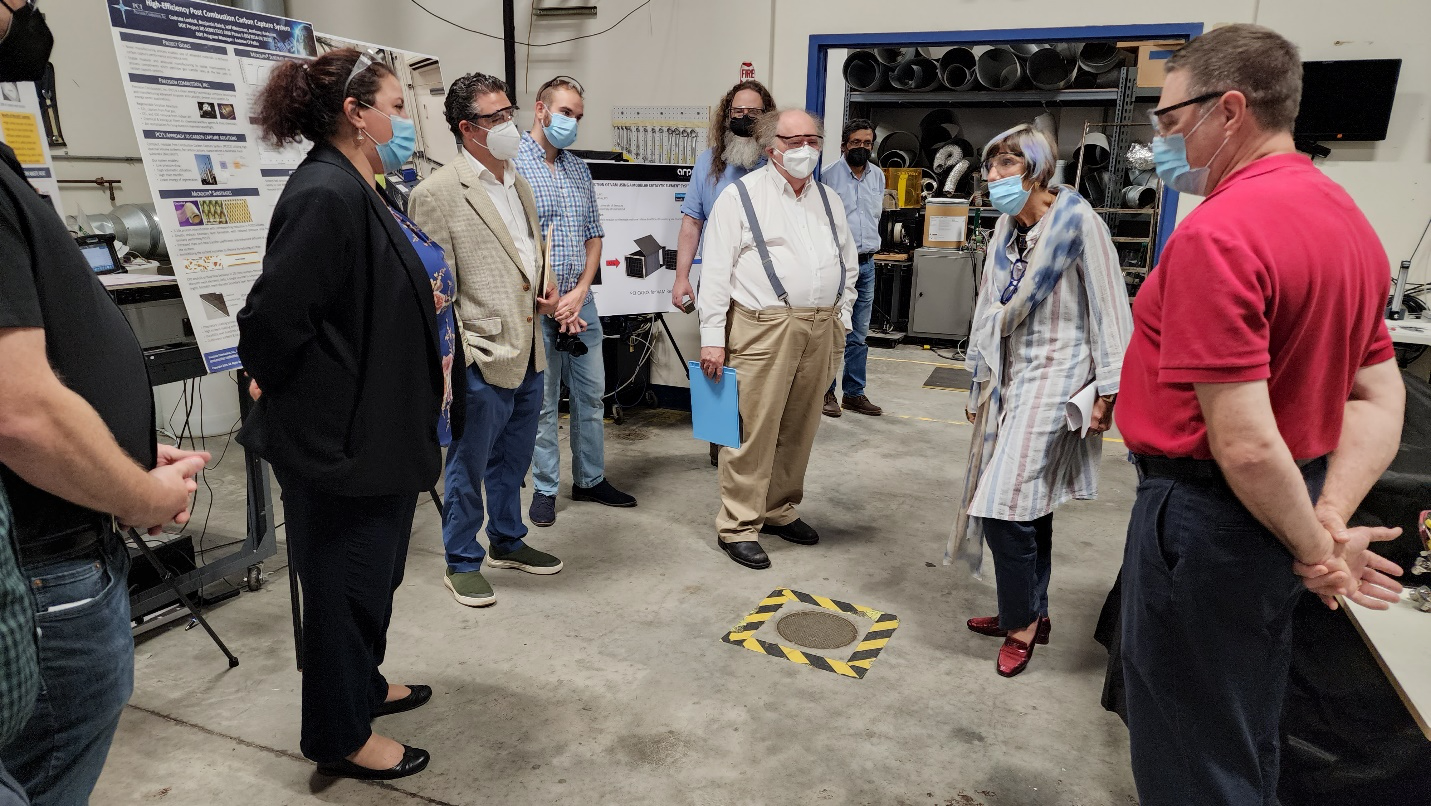

North Haven, CT (August 31, 2022) - Highlighting the recent Inflation Reduction Act and its effect on families, Congresswoman Rosa DeLauro (CT-3) visited Precision Combustion, Inc. (PCI) on Friday, August 26th. She reviewed new PCI technologies for clean and more efficient energy and for addressing climate change.

North Haven, CT (August 30th, 2022) - Precision Combustion, Inc. (PCI) has been awarded an Air Force Small Business Innovation Research Phase I program for a potentially transformative advancement in high-speed airbreathing propulsion systems. PCI will develop and demonstrate a new ignition and flame stabilization system that boosts fuel reactivity and flame speed for improved combustion efficiency and combustor stability.

North Haven, CT (July 20, 2022) – Precision Combustion, Inc. (PCI) received a highly competitive Small Business Innovation Research Phase I award from the Department of Energy (DOE) to develop PCI’s high efficiency technology for Direct Air Capture (DAC) of carbon dioxide (CO2) from air using low-cost waste heat sources, including from geothermal and data centers.

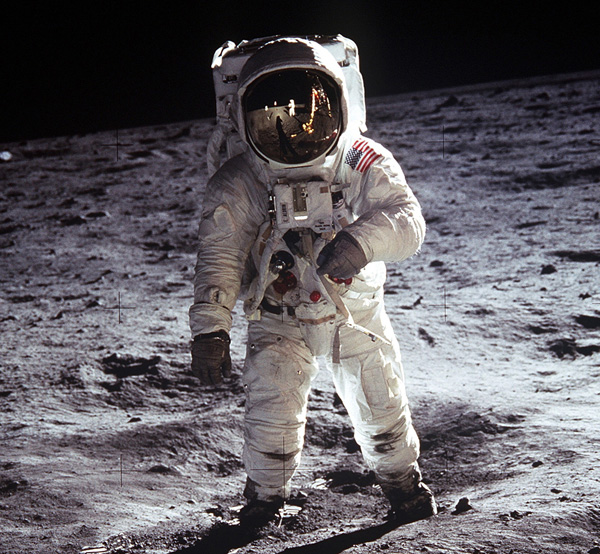

North Haven, CT (May 26, 2022) - Precision Combustion, Inc. (PCI) received a Small Business Innovation Research (SBIR) Phase I award from the National Aeronautics and Space Administration (NASA) to develop a regenerable dehumidification system technology for water management in reversible fuel cells. This system will remove over 99% of water from electrolysis products (hydrogen and oxygen gas) in a reversible fuel cell system using a combination of PCIís innovative high-capacity and regenerable adsorption methods, primarily for extraterrestrial applications.

North Haven, CT (May 20, 2022) – Precision Combustion, Inc. (PCI) will join over 340 innovators at the Department of Energy’s (DOE) Advanced Research Projects Agency-Energy (ARPA-E) annual Energy Innovation Summit in Denver, Colorado, which will be held May 23-25. PCI will showcase its advancements in solid-oxide fuel cell (SOFC) systems for aviation applications; specifically, for fuel-flexible, lightweight, gas-turbine hybridized for transportation. PCI’s SOFC’s for FLIGHT project received funding from ARPA-E’s “Range Extender for Electric Aviation with Low Carbon and High Efficiency” (REEACH) program in 2021, and PCI has continued to improve its prototypes and fuel cell systems as a result. PCI is also a participant on other ARPA-E projects in the REEACH program.

North Haven, CT (April 20th, 2022) - Precision Combustion, Inc. (PCI) was awarded a Small Business Innovation Research Phase I grant from the U.S. Department of Agriculture (USDA) for developing compact high effective technology to enhance apple and tree fruit productivity. PCI’s technology could revolutionize the control of ethylene, a naturally occurring gas generated by produce during ripening, transportation and storage. Ethylene stimulates ripening in many fruits and is also a byproduct of ripening, which if left unchecked leads to fruit aging and rotting. Control and removal of ethylene can extend the storage life and freshness of many fruits as well as certain vegetable crops while reducing spoilage.

North Haven, CT (April 4, 2022) – Precision Combustion, Inc. (PCI) announced today that PCI’s “Additively Manufactured Electrochemical-Chip Based Scalable Solid Oxide Fuel Cells” proposal was selected for award under the Advanced Research Project Agency-Energy (ARPA-E) 2021 OPEN program. The OPEN program supports novel approaches to the nation’s clean energy challenges.

North Haven, CT (February 14th, 2022) - Precision Combustion, Inc. (PCI) received a Small Business Innovation Research (SBIR) Phase I program award from the Department of Energy (DOE) to advance a cost competitive metallic-based membrane reactor for modular blue hydrogen production with CO2 capture from multi-feedstock gasification.

North Haven, CT (December 2, 2021)– Precision Combustion, Inc. (PCI) welcomed U.S. Department of Energy Secretary Jennifer Granholm, Connecticut Governor Ned Lamont and Commissioner of Connecticut’s Department of Energy & Environmental Protection (DEEP) Katie Scharf Dykes for a company tour and for the DOE to announce ARPA-E funding under the REMEDY program (Reducing Emissions of Methane Every Day of the Year), including an award to Precision Combustion.

North Haven, CT (October 27th, 2021) - Precision Combustion, Inc. (PCI) was awarded a Small Business Innovation Research (SBIR) Phase I program from the Navy for the development of a frangible coating that offers to significantly extend the maintenance and overhaul interval for critical "last chance" filters and other small passages in aircraft engines. This coating is set to reduce maintenance costs, enhance reliability, and improve Mean Time Between Failures (MTBF) for aircraft engines.

North Haven, CT (October 15, 2021) - Precision Combustion, Inc. (PCI) today congratulates PCI’s Dr. Marie Zuckerman for her recognition as Winner in the Small/Medium Business Innovation and Leadership category in this year’s Connecticut Women of Innovation® celebration held last night in a virtual event.

North Haven, CT (September 21, 2021) - Precision Combustion, Inc. (PCI) today congratulates two employees, Dr. Codruta Zoican-Loebick and Dr. Marie Zuckerman, Patent Agent, for their recognition as finalists in this year’s Connecticut Women of Innovation® competition. These awards recognize and celebrate Connecticut women for their achievements in STEM.

North Haven, CT (May 13, 2021) - Precision Combustion, Inc. (PCI) received an award from the NASA Phase II Small Business Innovation Research (SBIR) program for its compact, vacuum-regenerable sorbent bed for effectively removing a broad range of trace contaminants, which can be integrated with the Exploration Portable Life Support System (xPLSS) CO2/H2O removal system.

North Haven, CT (January 26th, 2021) - Precision Combustion, Inc. (PCI) has been recognized by Marcum LLP as the 2020 Marcum Tech Top 40 fastest growing Connecticut technology company in the Energy, Environment and Green Technologies category. Marcum based this on revenue growth from 2016 through 2019.

North Haven, CT (January 26th, 2021) - Precision Combustion, Inc. (PCI) has been recognized by Marcum LLP as the 2020 Marcum Tech Top 40 fastest growing Connecticut technology company in the Energy, Environment and Green Technologies category. Marcum based this on revenue growth from 2016 through 2019.

PCI is a clean energy technology company developing and manufacturing advanced catalytic and sorbent products and systems for energy and environmental sector applications. Growth has been driven by innovations across multiple fields, including fuel processing and fuel cell systems, compact power generation systems, air cleaning, and new materials technologies.

North Haven, CT (January 7th, 2021) - Precision Combustion, Inc. (PCI) announced it will participate in Department of Navy’s Forum for SBIR/STTR Transition (Navy FST) Events including NAVSEA Days, NAVAIR FST Days, and SEA-AIR-SPACE Symposium to showcase innovations in the removal of copper contamination from jet fuels, fuel cell system design, and air filtration. The company will present on its developing technologies and commercialization efforts and host booths to facilitate customer interactions.

North Haven, CT (September 14th, 2020 ) - Precision Combustion, Inc. (PCI) announced today that it has received a National Aeronautics and Space Administration (NASA) Small Business Technology Transfer (STTR) Phase I contract in collaboration with the University of Connecticut to develop a new fuel cell system design to meet NASA’s requirements for spacecraft fuel cell systems for use on the Moon and Mars.

North Haven, CT (September 2nd, 2020)  - Precision Combustion, Inc. (PCI) announced today that it was one of eight selected for award under the U.S. Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E) “Range Extenders for Electric Aviation with Low Carbon and High Efficiency” (REEACH) program. PCI’s project, “SOFCs for FLIGHT” will develop a hybrid solid oxide fuel cell (SOFC) power generator and energy storage system for all-electric propulsion of narrow-body commercial aircraft. ARPA-E’s REEACH program is driving the development of transformational energy technologies for extending the range of electric aircraft by converting carbon neutral liquid fuels (CNLFs) into electric power for aircraft propulsion and other systems.

- Precision Combustion, Inc. (PCI) announced today that it was one of eight selected for award under the U.S. Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E) “Range Extenders for Electric Aviation with Low Carbon and High Efficiency” (REEACH) program. PCI’s project, “SOFCs for FLIGHT” will develop a hybrid solid oxide fuel cell (SOFC) power generator and energy storage system for all-electric propulsion of narrow-body commercial aircraft. ARPA-E’s REEACH program is driving the development of transformational energy technologies for extending the range of electric aircraft by converting carbon neutral liquid fuels (CNLFs) into electric power for aircraft propulsion and other systems.

North Haven, CT (August 25th, 2020) - Precision Combustion, Inc. (PCI) announced today that it has received a National Aeronautics and Space Administration (NASA) SBIR Phase I contract to develop vacuum-regenerable trace contaminant control for NASA exploration portable life support systems (xPLSS).

North Haven, CT (August 4th, 2020) - Precision Combustion, Inc. (PCI) announced today it has won a Department of Energy (DOE) Phase I Small Business Innovation Research (SBIR) grant to develop a novel solid oxide fuel cell (SOFC) power generation system. PCI’s innovations offer improved efficiency for lower carbon footprint and produces a concentrated CO2 stream while using fossil fuels, the predominant energy source in the U.S.

North Haven, CT (July 21st, 2020) – Precision Combustion, Inc. (PCI) announced it has won a Department of Energy (DOE) Phase I Small Business Innovation Research (SBIR) grant to develop new technology for the Direct Air Capture (DAC) of carbon dioxide.

Carbon dioxide (CO2) emissions are driving global warming, with fossil fuel combustion and industry accounting for substantial CO2 emissions, as a result global economies and governments are trying to reduce these emissions. Carbon capture technologies provide an opportunity to reduce carbon emissions and utilize the CO2 for integration into value-added chains of several industries, such as enhanced oil recovery and an emerging industry of converting CO2 to fuels and plastics.

North Haven, CT (July 14th, 2020) - Precision Combustion, Inc. (PCI) announced a Department of Energy (DOE) Small Business Innovation Research (SBIR) Phase II award to continue the development of a catalytic process that selectively converts C2-C4 hydrocarbons to olefins while minimizing factors responsible for reduced product yields. This new process offers environmental and economic benefits while utilizing abundant domestic natural gas resources, including a 35% reduction in energy consumption compared to state-of-the art energy-intensive steam cracking. The process is suited for compact modular gas to fuels projects.

North Haven, CT (July 14th, 2020) - Precision Combustion, Inc. (PCI) announced a Department of Energy (DOE) Small Business Innovation Research (SBIR) Phase II award to continue the development of a catalytic process that selectively converts C2-C4 hydrocarbons to olefins while minimizing factors responsible for reduced product yields. This new process offers environmental and economic benefits while utilizing abundant domestic natural gas resources, including a 35% reduction in energy consumption compared to state-of-the art energy-intensive steam cracking. The process is suited for compact modular gas to fuels projects.

North Haven, CT (July 7th, 2020)  - Precision Combustion, Inc. (PCI) announced today it has won a two-year Department of Energy (DOE) Phase IIA Small Business Innovation Research (SBIR) grant to further develop a High-efficiency Post Combustion Carbon Capture System for reducing carbon dioxide emissions from power plants and other point sources.

- Precision Combustion, Inc. (PCI) announced today it has won a two-year Department of Energy (DOE) Phase IIA Small Business Innovation Research (SBIR) grant to further develop a High-efficiency Post Combustion Carbon Capture System for reducing carbon dioxide emissions from power plants and other point sources.

North Haven, CT (June 30th, 2020) - Precision Combustion, Inc. (PCI) received a Small Business Innovation Research (SBIR) Phase II program award from the Department of Defense to further develop a photovoltaic powered dehumidification system for individual combat vehicle interiors to reduce moisture build-up and corrosion, mold and fungal growth that could damage the vehicle.

North Haven, CT (January 16th, 2020) - Precision Combustion, Inc. (PCI) announced it has won a Navy Phase II Small Business Innovation Research (SBIR) contract to develop a compact, low pressure drop filter system for selective and efficient removal of metal contaminants from jet fuel without impacting the additive package or other fuel properties.

The Navy has experienced copper leaching that introduces contamination to JP-5 fuels. Dissolved copper in the fuels affects fuel decomposition, leading to coking, impaired engine performance and increased engine maintenance.

North Haven, CT (November 21st, 2019) - Precision Combustion, Inc. (PCI) has been recognized by Marcum LLP and the Connecticut Technology Council as the 2019 Marcum Tech Top 40 fastest growing Connecticut technology company in the Energy, Environment and Green Technologies category.

PCI is a clean energy technology company developing and manufacturing advanced catalytic products and systems for energy sector applications. PCI’s rapid growth has been driven by innovations across multiple fields, including fuel processing and fuel cell systems, compact power generation systems, and air cleaning and new materials technologies.

North Haven, CT (November 5th, 2019) - Precision Combustion, Inc. (PCI) is pleased to announce that it has been named a 2019 Marcum Tech Top 40 Finalist as one of the 40 fastest growing technology companies headquartered in Connecticut. The selection was announced today by The Connecticut Technology Council (CTC) and Marcum LLP that PCI made the Marcum Tech Top 40 (TT40) list and was selected in the Energy, Environment or Green Technology category. PCI was previously selected in 2018.

PCI is a clean energy technology company developing and manufacturing advanced catalytic products and systems for energy sector applications. PCI’s rapid growth has been driven by innovations across multiple fields, including fuel processing, fuel cell systems, compact power generation systems, and air cleaning and new materials technologies.

North Haven, CT (September 6th, 2019) - Precision Combustion, Inc. (PCI) announced today it has been awarded a U.S. Department of Agriculture Small Business Innovation Research (USDA SBIR) Phase I grant to develop a new technology to reduce indoor ammonia levels in broiler poultry facilities. Ammonia from chicken manure harms both chickens and farm workers, is a significant source of air pollutant, and current control practices can be a serious cost burden for poultry farmers.

North Haven, CT (January 23rd, 2019) - Precision Combustion, Inc. (PCI) announces it has been awarded Department of Energy (DOE) Phase I Small Business Innovation Research funding to develop a new Anion Exchange Membrane (AEM) for solar-to-hydrogen generation. The success of this innovation offers a path to higher performance, higher efficiency and lower cost production of hydrogen fuels from solar.

North Haven, CT (January 23rd, 2019) - Precision Combustion, Inc. (PCI) announces it has been awarded Department of Energy (DOE) Phase I Small Business Innovation Research funding to develop a new Anion Exchange Membrane (AEM) for solar-to-hydrogen generation. The success of this innovation offers a path to higher performance, higher efficiency and lower cost production of hydrogen fuels from solar.

PCI’s AEM technology will help enable significantly lower cost production of hydrogen from solar energy. This would both improve national energy efficiency and hydrogen costs, improving hydrogen availability and other technologies that would be supported by such broadened availability, with potential extension to other electrochemical energy storage and conversion devices. Overall, the technology will serve the public interest by advancing U.S. and DOE missions of energy efficiency, energy independence, and mitigating carbon dependence.

North Haven, CT (January 23rd, 2019) - Precision Combustion, Inc. (PCI) announced it has been awarded Department of Energy (DOE) Phase I Small Business Innovation Research funding to develop a catalytic process that selectively converts C2-C4’s to corresponding olefins while minimizing factors responsible for reduced product yields. This new gas to fuels process offers environmental and economic benefits while utilizing abundant domestic natural gas resources, resulting in a lower cost and reduced energy process compatible with projects from small scale to very large scale, as a direct replacement to state-of-the art energy-intensive steam cracking.

North Haven, CT (October 4th, 2018) - In the Marcum Tech Top 40 award ceremony last night, Precision Combustion, Inc. (PCI) was recognized as Connecticut’s Fastest Growing Company in the Energy, Environment & Green Technology category.

PCI is a clean energy technology company developing and manufacturing catalytic products and systems for energy sector applications. PCI’s rapid growth has been driven by innovations in multiple fields, including fuel processing and fuel cell systems, compact power generation systems, high performance burners; and combustion systems, new materials and specialty chemical reactor systems. The company has 48 employees and is currently hiring.

North Haven, CT (August 29th, 2018) - Precision Combustion, Inc. (PCI) today announced it will host a booth for the first time at Modern Day Marine, the foremost trade fair for everything Marine Corps related, taking place September 25-27, 2018 at Marine Corps Base Quantico, VA.

North Haven, CT (August 28th, 2018) - Precision Combustion, Inc. (PCI) is developing an ultra-compact, high performance hydrogen generator as a new automotive component for improving gasoline engine efficiency and emissions. The Department of Energy (DOE) Vehicle Technologies office, through the Small Business Innovation Research (SBIR) program, has been supporting PCI in this development, and has now has expanded that support under a new SBIR Phase IIB award. The additional funding will be used to support advanced component development and automobile testing for OEM customers.

North Haven, CT (August 22nd, 2018) - Precision Combustion, Inc. (PCI) is pleased to announce that it has been named to the Marcum Tech Top 40 as one of the 40 fastest growing technology companies headquartered in Connecticut.

PCI is a clean energy technology company developing and manufacturing catalytic products and systems for energy sector applications. PCI’s sustained growth has been driven by innovations in multiple fields including fuel processing and fuel cell systems, compact power generation systems, high performance burners and combustion systems, new materials and specialty chemical reactor systems.

North Haven, CT (August 13th, 2018) - Precision Combustion, Inc. (PCI) announced it has won a Department of Energy Phase II Small Business Innovation Research grant to develop a novel High-Efficiency Post Combustion Carbon Capture System.

Energy requirements dominate current carbon dioxide capture economics. PCI’s new technology directly tackles the energy cost challenge, developing a high capability nanosorbent on a tailorable support that offers the opportunity to significantly improve the efficiency of CO2 removal from post combustion exhaust. Benefits also include suitability for rapid heat transfer and low temperature swing regeneration operating modes needed for cost-effective carbon capture.

North Haven, CT (August 2nd, 2018)  - Precision Combustion, Inc. (PCI) has won a Department of Defense Navy Small Business Innovation Research (SBIR) contract to develop its new filter technology for liminating copper contaminant from Navy aircraft JP-5 fuel.

- Precision Combustion, Inc. (PCI) has won a Department of Defense Navy Small Business Innovation Research (SBIR) contract to develop its new filter technology for liminating copper contaminant from Navy aircraft JP-5 fuel.

Maintenance costs from copper contamination are projected at $1 billion annually for the Navy’s fleet and Joint Strike Fighter programs which has generated strong interest for resolving this issue. Current fuel piping on aircraft carriers and in supply ships contains copper nickel alloys, which is primarily responsible for the issue, resulting in additional aircraft maintenance and decreased performance.

North Haven, CT (July 6th, 2018) - Precision Combustion, Inc. (PCI) announced today that it has received a Department of Defense (DOD) NAVY SBIR Phase I contract to develop a breakthrough technology enabling a new logistics-fueled, high efficiency all-electric power and propulsion (PnP) system with potential to improve mission range and logistics for Navy UAS platforms.

The proposed technology will enable advancement in all-electric PnP systems fueled with military logistics fuels and jet fuels. This fuel cell system offers multiple notable capability improvements for UAS compared to the current IC engine solutions, including higher efficiency, increased mission duration and reduced acoustic signature. A major objective of the project is to provide a proof-of-concept system solution and design to address the needs for increasing mission duration while decreasing operating costs through reduced maintenance cycle.

North Haven, CT (February 19th, 2018) - Precision Combustion, Inc. (PCI) announced today that it has won a Department of Energy (DOE) SBIR Phase I grant to develop a novel process to produce valuable fuels and products from waste carbon dioxide (CO2) using excess renewable electricity, permitting carbon neutral or positive performance.

The flexible nature of PCI’s approach lends itself to accommodate intermittent renewable sources of energy, including wind- and solar-generated electrical power. PCI’s innovation will be applicable to a wide range of CO2 sources, including fossil fuel power plants, cement plants and other low- and high-volume industrial sources. This waste CO2 will be used to manufacture diesel and jet fuels and a range of chemicals, directly replacing petroleum-sourced products. PCI’s process utilizes renewable electricity, which is often produced in quantities well in excess of demand, providing improved load leveling and stability in power grids.

North Haven, CT (February 26th, 2018) - Precision Combustion, Inc. (PCI) announced today that it has won a Department of Energy (DOE) SBIR Phase I grant to develop novel materials and processes for separating and purifying ethylene, an important commodity chemical and principal feedstock for manufacturing a wide range of industrial and consumer products.

North Haven, CT (February 26th, 2018) - Precision Combustion, Inc. (PCI) announced today that it has won a Department of Energy (DOE) SBIR Phase I grant to develop novel materials and processes for separating and purifying ethylene, an important commodity chemical and principal feedstock for manufacturing a wide range of industrial and consumer products.

PCI’s approach will be economically beneficial to both large to small scale ethylene producers. Ethylene is used extensively as a building block in chemical and petrochemical industry and can be converted industrially into a variety of intermediate and end products, with polyethylene production a primary consumer. PCI’s will demonstrate the ability to selectively separate ethylene from the impurities inherently formed during synthesis processes as well as unreacted feedstocks, replacing current high cost and process-intensive cryogenic distillation with a low-impact and low energy sorption-based process.

North Haven, CT (November 21st, 2017) - Precision Combustion, Inc. (PCI) announced today that it has upgraded the lighting in its 38,000 square foot office and industrial plant building. The upgrade to LED lighting will save roughly 80,000 kilowatt-hours per year, equivalent to the electricity used by 7 average houses while reducing PCI’s carbon footprint by about 100,000 pounds of CO2 emissions annually.

North Haven, CT (November 21st, 2017) - Precision Combustion, Inc. (PCI) announced today that it has upgraded the lighting in its 38,000 square foot office and industrial plant building. The upgrade to LED lighting will save roughly 80,000 kilowatt-hours per year, equivalent to the electricity used by 7 average houses while reducing PCI’s carbon footprint by about 100,000 pounds of CO2 emissions annually.

North Haven, CT (October 19th, 2017) - Precision Combustion, Inc. (PCI) announced today that it has expanded its family of diesel and military logistics fueled lightweight tactical generators to include 300 W and 450 W as well as the existing 1, 2 and 3 kW variants. These generators have electric start and battery-hybridized versions with direct battery-charging capability. The 450W version meets or beats the latest requirements for the Army’s Platoon Power Generator (PPG) program that enables use of NETT Warrior radios and systems with tactical power generation for battery charging.

North Haven, CT (October 19th, 2017) - Precision Combustion, Inc. (PCI) announced today that it has expanded its family of diesel and military logistics fueled lightweight tactical generators to include 300 W and 450 W as well as the existing 1, 2 and 3 kW variants. These generators have electric start and battery-hybridized versions with direct battery-charging capability. The 450W version meets or beats the latest requirements for the Army’s Platoon Power Generator (PPG) program that enables use of NETT Warrior radios and systems with tactical power generation for battery charging.

PCI’s 1 kW heavy fuel generator has demonstrated more than 1,000 hours of operation with thousands of hours accumulated across the platform. The systems meet MIL-STD requirements for environmental performance and power quality, including high power DC and AC outputs.

North Haven, CT (September 22nd, 2017) - Precision Combustion, Inc. (PCI) has received a Department of Energy SBIR Phase II award supporting PCI’s development of a novel approach for using solar energy to make liquid fuels from natural gas and carbon dioxide.

PCI’s process efficiently integrates on-sun capture with off-sun release of solar energy while simultaneously producing cost-competitive fuel and chemical products. The process uses a new multi-functional material designed to reversibly store and release high-grade solar energy as needed, while enabling process intensification to upgrade natural gas and carbon dioxide into more valuable liquid fuel components and chemicals.

North Haven, CT (June 8th, 2017) - Precision Combustion, Inc. (PCI) announced today that it has received a National Aeronautics and Space Administration (NASA) SBIR Phase I contract to develop a new technology for regenerative solid oxide fuel cell stacks.

The proposed technology will allow for advancement in the reformation of off-gases such as high hydrocarbons as well as methane within a solid oxide fuel cell (SOFC) stack. Novel structural elements allow direct internal reforming of lunar or Martian off-gases (e.g., methane and high hydrocarbons) within a solid oxide fuel cell stack as well as efficient H2O/CO2 electrolysis in the same stack, overcoming shortcomings of traditional approaches. The resulting design offers the potential for lighter weight and simpler stack design, with higher efficiency and durability.

New Haven, CT (May 17th, 2017) - Precision Combustion, Inc. (PCI) sponsored the Energy and the Environment Award again this year at the New Haven Public Schools Science fair. PCI commonly gives out three awards for projects relating to energy or environmental topics each year. The science fair is a great event with students from Pre-K (5 years old) through Grade 12.

The New Haven science fair started back in 1995 with seven schools. However, the science fair has now grown to 43 schools and over 8,000 New Haven students which joined in the fun of hands-on science, promotion of skills in critical thinking, and practice of the scientific process.

North Haven, CT (April 26th, 2017) - Precision Combustion, Inc. (PCI) announced today it has been awarded a NASA Phase II Small Business Innovation Research (SBIR) project for its Trace Contaminant Control System (TCCS) technology for Advanced Spacesuit Applications.

PCI is developing a lightweight and regenerable TCCS for spacesuits. Astronauts breathe recycled air, and spacesuit air must be cleaned of trace contaminants such as ammonia and organic compounds to keep the air safe and maintain crew comfort. PCI’s proposed system uses a novel long-life nanomaterial sorbent to capture the contaminants, with periodic on-suit vacuum regeneration to remove them from the system. Unlike currently-used activated charcoal beds that cannot be regenerated and that are bulky, require frequent replacement, and have high life cycle operating cost, PCI’s sorbent is very compact and regenerable, has high sorption capacity, requires less energy for operation, and can be tailored to targeted requirements. A regenerable TCCS technology will help enable longer Extravehicular Activity (EVA) missions.

PCI is developing a lightweight and regenerable TCCS for spacesuits. Astronauts breathe recycled air, and spacesuit air must be cleaned of trace contaminants such as ammonia and organic compounds to keep the air safe and maintain crew comfort. PCI’s proposed system uses a novel long-life nanomaterial sorbent to capture the contaminants, with periodic on-suit vacuum regeneration to remove them from the system. Unlike currently-used activated charcoal beds that cannot be regenerated and that are bulky, require frequent replacement, and have high life cycle operating cost, PCI’s sorbent is very compact and regenerable, has high sorption capacity, requires less energy for operation, and can be tailored to targeted requirements. A regenerable TCCS technology will help enable longer Extravehicular Activity (EVA) missions.

North Haven, CT (April 17th, 2017) - Precision Combustion, Inc. (PCI) announced it has been awarded Department of Energy (DOE) Phase IIA Small Business Innovation Research funding to develop a long-sought direct method to convert shale-gas methane into ethylene or fuels in a direct and compact process. This new shale-gas to fuels process offers environmental and economic benefits while utilizing abundant domestic natural gas resources.

North Haven, CT (April 17th, 2017) - Precision Combustion, Inc. (PCI) announced it has been awarded Department of Energy (DOE) Phase IIA Small Business Innovation Research funding to develop a long-sought direct method to convert shale-gas methane into ethylene or fuels in a direct and compact process. This new shale-gas to fuels process offers environmental and economic benefits while utilizing abundant domestic natural gas resources.

PCI’s approach offers substantial energy savings with significantly reduced process complexity and capital intensity, as compared to industrially practiced large-scale indirect routes which include methane-steam reforming, followed by water-gas shift, and then methanol synthesis or Fischer-Tropsch upgrading.

North Haven, CT (February 7th, 2017) – Precision Combustion, Inc. (PCI) announced it has been awarded a Department of Defense (DOD) Phase I Small Business Innovation Research funding to develop a soldier portable, flameless, thermal to electric battery charger, capable of being fueled by a variety of fuels. This will provide the ability to charge batteries in the field, thus reducing the number of batteries typically required for an extended mission and reducing the pack weight for the soldier.

North Haven, CT (February 7th, 2017) – Precision Combustion, Inc. (PCI) announced it has been awarded a Department of Defense (DOD) Phase I Small Business Innovation Research funding to develop a soldier portable, flameless, thermal to electric battery charger, capable of being fueled by a variety of fuels. This will provide the ability to charge batteries in the field, thus reducing the number of batteries typically required for an extended mission and reducing the pack weight for the soldier.

North Haven, CT (August 2nd, 2016) - Precision Combustion, Inc. (PCI) announced today it has been awarded a NASA Phase I Small Business Innovation Research (SBIR) project for its Trace Contaminant Control System for Advanced Spacesuit Applications.

Astronauts breathe recycled air, and spacesuit air must be cleaned of trace contaminants such as ammonia and organic compounds to keep it safe. PCI’s proposed system uses a novel long-life nanomaterial sorbent to capture the contaminants, with on-suit vacuum swing regeneration to clean them from the system. Unlike currently-used activated charcoal beds that cannot be regenerated and that are bulky, require frequent replacement, and have high life cycle operating cost, PCI’s sorbent is ultra-compact and regenerable, has high sorption capacity, and can be tailored to targeted requirements. This new technology offers the potential for much longer spacesuit mission duration while reducing volume, weight, consumables dependence, and energy consumption.

North Haven, CT (July 12th, 2016) - Precision Combustion, Inc. (PCI) announced a Department of Energy (DOE) SBIR Phase I award to explore a new reforming system for more fully using refinery gas, or still gas, to produce hydrogen for internal refinery needs. The proposed system uses advanced Microlith® catalysts, with the goal of enabling refineries to more fully use still gas as a feedstock for hydrogen production, improving refinery energy efficiency with increased operational flexibility and reduced greenhouse gas emissions.

North Haven, CT (June 30th, 2016) - Precision Combustion, Inc. (PCI) announced today that it has won a competitive Department of Energy (DOE) SBIR Phase I grant to develop a new material and technology for using solar energy to make fuel.

PCI’s technology converts intermittent solar energy to transportation fuels by alternatively capturing and releasing of solar energy convert carbon dioxide and methane, abundantly available in both natural gas and shale gas, for use in scalable processes to manufacture fuels or chemicals. This novel combination of concentrated solar power collector and effective materials-based process, plus other design features, provides process intensification for cost effective enablement of CO2 conversion to fuels.

North Haven, CT (April 7th, 2016) - Precision Combustion Inc. (PCI) announced today that it has been awarded a Department of Energy Phase I Small Business Technology Transfer (STTR) grant in partnership with University of Connecticut to develop and validate a predictive multi‐scale combustion modeling tool to optimize the design and operation of a spouted bed reactor. Spouted beds are an advanced fluidized bed reactor which offers the potential for higher fuel conversion efficiency and emissions with improved operating cost. The modeling tool will help guide new designs for substituting renewable biomass in coal-fed boilers while improving efficiency and reducing emissions. It is also expected to decrease the cost and time associated with the development of such co-fired boilers.

North Haven, CT (March 29th, 2016) - Precision Combustion, Inc. (PCI) today announced it is part of the largest-ever U.S. delegation to Hannover Messe, the world’s foremost trade fair for industrial technology, taking place April 25-29, in Hannover, Germany. For the first time in the Fair’s history, the United States will be the Partner Country, a status that provides the more than 390 businesses and organizations in the U.S. delegation an unprecedented opportunity to be prominently featured throughout the event. President Obama will also participate in this year’s event, themed "Integrated Industry-Discover Solutions."

North Haven, CT (February 29th, 2016) - Precision Combustion, Inc. (PCI) announced a major step forward for its regenerable air filter technology for removing VOCs and carbon dioxide from indoor air, with the Environmental Protection Agency (EPA) selecting PCI for a highly-competitive Small Business Innovation Research (SBIR) Phase II contract. Successful implementation of the technology in conjunction with a Demand Control Ventilation (DCV) system in a building offers potential for better indoor air quality (IAQ) with reduced building energy consumption. By directly removing these pollutants from indoor air, the air can be made cleaner while reducing the use of ventilation with outdoor air that needs to be heated or cooled and humidity-controlled. The U.S. Energy Information Agency estimates 41% of America’s energy is used in residential and commercial buildings – reducing the need for “make-up” outdoor air and its energy costs could save significant energy and equipment costs and reduce global warming.

North Haven, CT (September 1st, 2015) - Precision Combustion Inc. (PCI) announced today that it has been awarded an Environmental Protection Agency (EPA) SBIR Phase I grant to develop novel functionalized carbon nanomaterials for use in air filters, especially for removal of Volatile Organic Compounds (VOCs) from indoor air.

Current building filtration systems do not generally remove VOCs from the air, mostly relying upon diluting the VOC load with cleaner outdoor air to moderate VOC build-up. PCI proposed tunable nanosorbents offer the potential for a number of advantages, including design-enhanced effectiveness for targeted VOCs, improved regenerability, and effectiveness across a wider range of VOCs compared with existing filter materials. In volume, the materials need not be expensive, yet they could be much more effective than conventional materials for their intended purpose. A nanostructured air filter could achieve more reliable levels of indoor air quality, while reducing the requirement for makeup air, lowering energy use, and providing operating and capital cost savings.

North Haven, CT (June 25, 2015) - The Free Piston Stirling Engine Based 1 kW generatorTeam led by Sunpower Inc. (Athens, OH) along with its research partners Precision Combustion, Inc. (PCI) and Aerojet Rocketdyne (Arlington, Virginia) has been selected for a $3,500,000 award from the Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E)’s GENerators for Small Electrical and Thermal Systems (GENSETS) project, which aims to develop generator technologies that will improve efficiencies in residential Combined Heat and Power (CHP) generation.

North Haven, CT (May 28, 2015) - Precision Combustion, Inc. (PCI) of North Haven, CT, is pleased to announce its selection as a 2015 winner of the Tibbetts Award, which honors high-tech small businesses for excellence in research and development for the Federal government and for their success in innovating new technology and products. The U.S. Small Business Administration (SBA) in 2015 has selected 23 small businesses for this award from among the participants in the Federal Small Business Innovation Research (SBIR) program.

North Haven, CT (April 27th, 2015) - Precision Combustion Inc. (PCI) announced today that it has been awarded a Department of Energy (DOE) SBIR Phase II grant to develop a new compact and scalable catalytic reactor for converting natural gas directly to commodity chemicals.

Precision Combustion, Inc. is developing a long-sought method to directly convert shale-gas methane into fuels or value-added chemicals that avoids the high energy cost, large intensive processing units, and large upfront investments required by conventional multi-step technologies. PCI’s approach is compact, field deployable, scalable, and offers a potential breakthrough in energy efficiency and yield for converting methane-rich shale gas to ethylene or other chemicals in a single step. Ethylene has large value in the commodity market as a primary petrochemical intermediate and feedstock for both chemicals and fuels.

North Haven, CT (October 21st, 2014) - Precision Combustion Inc. (PCI) announced today that it has been awarded a USDA National Institute of Food and Agriculture (USDA-NIFA) SBIR Phase II grant to develop a prototype for a compact mobile soil steaming system for soil disinfestation. This project offers to enhance U.S. agricultural productivity, reduce chemicals use in crop production, and increase availability of organically grown foods.

North Haven, CT (July 14TH, 2014) - Precision Combustion Inc. (PCI) announced today that it has been awarded a U.S. Environmental Protection Agency (EPA) SBIR Phase I Grant to develop a regenerable Indoor Air Filter for VOC and other gaseous pollutant removal.

The quality of indoor air varies substantially. Most modern buildings including homes maintain indoor air with a combination of particulate filters and make-up air. The filters remove particulates while newly drawn in outdoor air (“make-up air”) replaces indoor air that is exhausted from the building through ventilation, leaks and/or combustion processes. Particulate filters alone are ineffective in removing gaseous pollutants (such as formaldehyde, benzene, most odors, other organics and ammonia) or CO2.

North Haven, CT (March 12th, 2014) - Precision Combustion Inc. (PCI) has been awarded a DOE SBIR Phase I grant to prove its novel concept for a potentially-breakthrough process for converting natural gas directly to commodity chemicals. During Phase I, PCI will develop experimental validation of its new approach.

An efficient direct process, a long-sought goal of the refining industry, will enable the use of inexpensive domestic supplies of natural gas in place of expensive crude oil for production of America’s industrial chemicals. There has been much work by others to this goal because of the potential for large capital investment and energy savings. Despite this extensive investigation, a direct chemical pathway remains problematic due to reaction engineering constraints.

North Haven, CT (June 17th, 2013) - Precision Combustion Inc. (PCI) announced today that it has been awarded an EPA SBIR Phase I grant to develop and demonstrate a fuel flexible, low emission burner for biomass derived gas used in waste-to-energy systems.

The economics of biomass gasification waste-to-energy (WTE) plants can be greatly improved by enabling plant operators to be more opportunistic in their choice of biomass input feedstock without combustion problems resulting from gases with different heating values and chemistries. These wastes include a wide range of bio-based fuel stocks (biomass from wood and/or grasslands) or organic waste streams (manure and farm waste, municipal solid waste (MSW), sawdust). Plant operators need a single burner solution that can effectively handle a variety of gas compositions without pre-treatment.

North Haven, CT (August 6th, 2012) - Precision Combustion, Inc. (PCI) is pleased to announce that for the third consecutive year it has been named to the Marcum Tech Top 40 as one of the 40 fastest growing technology companies headquartered in Connecticut.

PCI is a clean energy technology company developing and manufacturing catalytic devices and systems for energy sector applications. PCI’s sustained growth has been driven by multiple innovations in its fields of fuel processing, high performance burners and combustion systems, and specialty chemical reactor systems. Since 2009 the number of employees at PCI has grown by 60%.

North Haven, CT (May 8th, 2012) - Precision Combustion Inc. (PCI) announced today that it has won an Army SBIR Phase I award to develop a compact and high performance regenerable air filter media and system to protect building and other infrastructure occupants against toxic airborne chemicals.

Airborne toxic industrial chemicals (TIC’s) pose a threat to military and homeland security personnel as well as to the public. Current carbon-based chemical adsorbent filters have limited lifespans and cannot be regenerated, resulting in high maintenance cost and safety concerns.

North Haven, CT (January 9th, 2012) - Precision Combustion Inc. (PCI) announced today that it has been selected for a NASA STTR Phase I award in collaboration with the University of Hartford for a compact, regenerable, low power adsorber for Spacesuit CO2, Humidity, and Trace Contaminant Control.

Trace contaminants generated via metabolic processes, off-gassing of spacesuit materials, and other by-products are introduced into the ventilation loop of a spacesuit and must be removed. However, current approaches to space suit atmosphere revitalization, though effective, are non-regenerable in space, incompatible with each other and also have significant power consumption associated with high life cycle operating cost. PCI proposes an ultra-compact regenerable CO2, water and trace contaminant removal system, which will contribute to a light-weight, efficient Trace Contaminant Control system with reduced power consumption and cost. In conjunction with Professor Thomas Filburn at University of Hartford, the Phase I effort will demonstrate proof of concept. The effort will also aim to analyze effective and rapid regeneration with an operating demonstration on a bench scale using selected trace contaminants.

North Haven, CT (August 29th, 2011) - Precision Combustion Inc. (PCI) announced today that it has been awarded a DOE SBIR Phase I Grant for Steam–Based In-Situ Soil Remediation. Mercury is found as a contaminant at 290 Superfund National Priority sites. Thermal treatment of this mercury and its compounds, whether above ground on removed contaminated materials or in-ground, is highly effective in removing more than 90% of mercury in place but is dependent on site-specific factors. Temperatures greater than 300oC are usually required to meet land disposal standards. Treating mercury in ground avoids the added hazards of transporting contaminant soil to a treatment facility and reduces exposure risks.

North Haven, CT (August 2nd, 2011) - Precision Combustion, Inc. (PCI) is pleased to announce that it has been named to the 2011 Marcum Tech Top 40 as one of the 40 fastest growing technology companies headquartered in Connecticut. PCI was also on the 2010 Marcum Tech Top 40. The Connecticut Technology Council (CTC) and Marcum LLC celebrate the state’s continued economic growth by highlighting the businesses leading the way in successful technological innovation. The Marcum Tech Top 40 identifies the fastest growing technology companies based on percentage revenue growth over a four year period. Winners of this award must have at least $3 million in revenue and are placed in six technology categories: Software, IT Services, New Media/Internet/Telecom, Life Sciences, Advanced Manufacturing, and Energy/ Environmental Technology. PCI is recognized among four additional outstanding Energy/Environmental (green) Technology companies. 12 of this year’s selections have publicly-listed securities; the other 28 are private.

North Haven, CT (July 12th, 2011) - Precision Combustion, Inc. (PCI) is developing a novel high performance heat exchanger for waste heat recovery designed for the aggressive conditions of a gas turbine in marine applications. Heat recovered would be utilized for auxiliary electrical generation (i.e. used to drive an Organic Rankine Cycle, thermo-electric generators, or Stirling engines). Recovering waste heat lost from a gas turbine and diesel engine offers the potential for significant fuel savings, improved cycle efficiency and additional electricity for on board marine applications. The design of a heat recovery device for this application is challenging due, in part, to highly transient engine operation, limitations on pressure drop, and weight and space constraints. PCI will explore a new approach towards a durable, simple, compact and efficient heat recovery heat exchanger addressing these issues.

North Haven, CT (June 1st, 2011) - The Navy has chosen PCI’s Microlith® fuel reformer and fuel processor development as a Navy Small Business Innovation Research (SBIR) Success Story.

Fuel cells offer the potential for significantly improved mission performance and efficiency compared to conventional internal combustion engines. To achieve these improvements, fuel cell stacks must be able to operate on available logistic liquid fuels such as JP-8 rather than the hydrogen fuels they normally require. PCI’s Compact Logistics Fuel Processor efficiently converts conventional liquid fuels such as JP-8 to a hydrogen-rich gas that can be used in fuel cells. As a result, the technology offers a practical fueling solution to the military’s desire to use fuel cells.

North Haven, CT (January 6th, 2011) - Precision Combustion, Inc. (PCI) announced today that its Novel, Regenerable Microlith® catalytic reactor for CO2 Reduction via Bosch process has been selected for award of a NASA Small Business Innovation Research (SBIR) Phase I contract. Current air revitalization systems onboard manned space missions remove CO2 from the cabin air and then vent it overboard. The Bosch reaction uses hydrogen as a means to produce water from carbon dioxide, potentially closing the loop in cabin atmosphere revitalization systems.

North Haven, CT (January 5th, 2011) - NASA has selected PCI to develop a novel Microlith® CO2 adsorber, separator and Methanation system for spacecraft/space habitat oxygen and fuel production. The award is being made under a NASA Small Business Innovation Research (SBIR) Phase I program.

PCI will be developing a CO2 separator and methanation reactor to effectively separate CO2 from the Martian atmosphere and to produce methane (CH4) and water vapor by reacting the collected CO2 with H2. A Microlith®-based, regenerable CO2 adsorber/separator will be integrated with a compact and lightweight Microlith®-based reactor. CO2 conversion in the methanation reactor is expected to be greater than 90% with CH4 selectivity of as high as 100%. While thin, the Mars Atmosphere is comprised almost entirely of carbon dioxide. The technology will provide the potential for use of Mars in-situ resources for producing fuel and oxygen to extend the range of human/robotic planetary exploration.